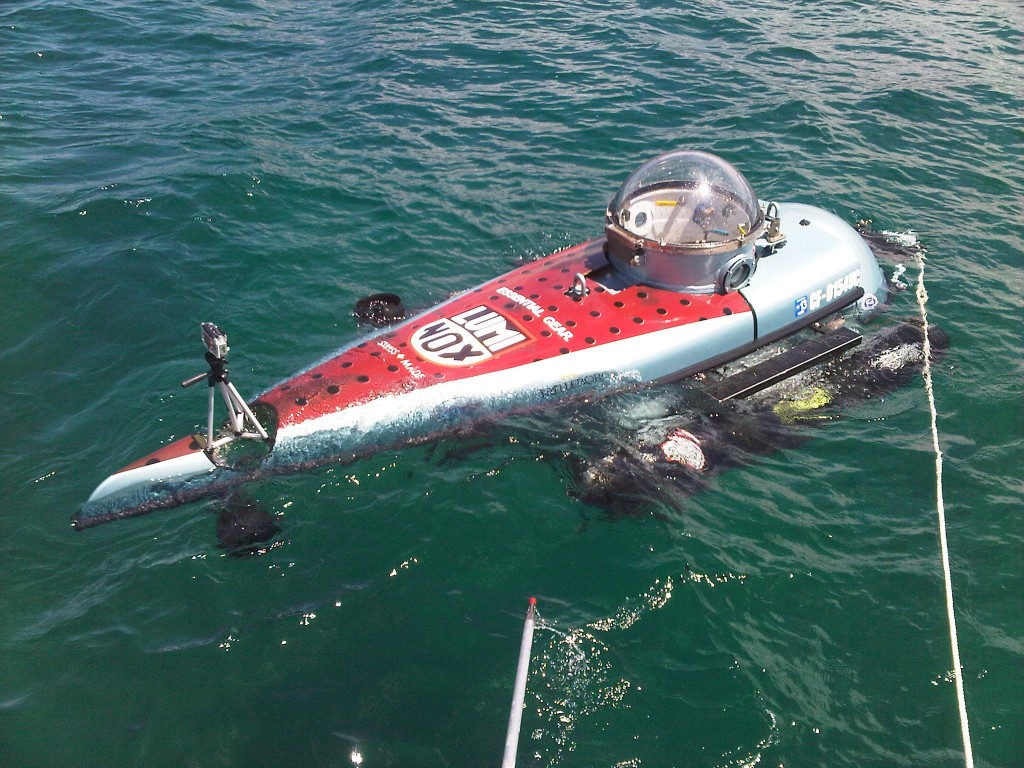

Last weekend, Undersea Voyager Project founder and Shark Hero Scott Cassell took his submarine on a test dive to 500 feet deep. The dive was a complete success.

Below is Scott’s account of the dive in the “Great White.”

How deep is 500 feet deep?

Look at a 50 story building and think of the height. Now, think of the view when you are on the top floor of that building looking down. People look like ants they are so far below you. That’s how deep our little sub, Great White was this last Sunday!

The Deep Dive Team consisted of Tom Loomis, Sid Loomis, Scott Reed and myself (Scott Cassell).

We all grouped together at the Loomis home on Saturday, August 11th, in the morning and spent the day prepping the sub by adapting the ballast tubes to be remotely inflated with a 500 foot air-hose (made up of 74 different air-hoses joined together… Ok… maybe Im exaggerating just a little…. but it was a bunch of them).

We all grouped together at the Loomis home on Saturday, August 11th, in the morning and spent the day prepping the sub by adapting the ballast tubes to be remotely inflated with a 500 foot air-hose (made up of 74 different air-hoses joined together… Ok… maybe Im exaggerating just a little…. but it was a bunch of them).

We also used the Deep Sea Power & Light’s new Nano-Cam to monitor the interior of the sub during tests with 1,000’ cable giving us a real-time image… which added to the stress level (I’ll explain later).

The strength member was a series of ropes tied together and then marked by Tom and Carrie in 50 foot increments down to 500 feet.

Then came the fun part. Tom, Scott Reed and I man-handled two 160 pound slabs of lead up six feet high (over my head but only chest high for Tom ‘the human crane’) up and into the conning tower of the sub… while being precise and delicate of their placement so we did not damage the hull or valves inside the sub… I was lifting and shaking… and Tom was barely breaking a sweat.

Under the direction of Carrie Loomis’ accurate notation (from her previous dive records), we loaded lead bricks and a water tank until Carrie’s numbers indicated we had arrived at neutral buoyancy. During unmanned dives… this a critical factor!

Scott Reed removed all the electronics and equipment not required for the test while I made-ready the pontoon inflation system and removed the thrusters. The next-to-the-last step was the hi-tech water ingress detection system invented by Scott Reed. After much thought, design and deliberation (several seconds), he concluded that construction paper taped to the conning tower that was in full view of the DSP&L Nano-Cam… was the best option. That way if water enters the sub during the un-manned dives the paper would change color and the live-camera feed would show it and we could bring the sub up immediately by remotely inflating the ballast pontoons.

Tom Loomis designed a simple ratchet strap closing method for the dome-hatch while Scott Reed figured how to use clamps to the hinge and nose areas.

We were ready…!

Sunday

We launched the Great White at Tahoe Keys Marina at 0830, prepped the sub for dives, turned on a spot light inside the sub, then towed her out with the M/V Blue Diver to the first drop Dive Site of 25 feet.

After about 20 minutes, we organized the cables, ropes and hoses to the point where we could dive. Sid jumped in the water (without a wetsuit!) and using small wrenches, she opened the ballast exhaust valves manually and vented the sub (then quickly closed them) sending the Great White gently to the bottom. The buoyancy was perfect! (Carrie’s numbers were precisely accurate) After five minutes, I opened the SCUBA tank connected to the inflation hose… and the Great White’s ballast pontoons inflated bringing her to the surface perfectly! With the system proven, we readied for the next test dive.

Since I already manned-test dove her to 100 ffw, I decided the next depth should be 150 ffw.

We towed the sub to deeper water and repeated the steps sending the Great White to 150 ffw. With Scott Reed glued to the video monitor he noted that a few water drops were visible on the water-indicating paper but they were small and did not continue. we raised her to the surface and realized that each team member had to work in synchronicity with their hose, cable or line to bring onto the Blue Diver’s deck and stow cleanly so it could be easily deployed for the next dive. Once Great White surfaced, Sid swam around her carefully checking for any evidence of leaking. The sub looked perfect! Again, we towed her to deeper water.

As before, we lowered the sub down, this time to 250 ffw. and noticed that very little ambient light was available making Scott Reed rely almost entirely on the spot light to see inside the sub. We re-surfaced the sub and checked her for leaks or failures… and we found none!

Moving to deeper water the tension and confidence increased. This time we were going deeper than she had ever been before in a fully operational state. (In the 1970‘s, our K-250 hull was pressure tested to 500 feet by CAPT Kittredge, but all openings on the sub were blocked with steel “plugs”. This time, she has acrylic ports, electrical thru-hulls and gas valve systems onboard.

Sid opens the ballast pontoon valves and she began her descent to 400 ffw. Scott Reed remain silent as he watched the monitor as the Great White entered the lightless realm. Even though the video feed in real time was critical… it added an unpredicted level of stress. We could see what was happening turning each dive into a movie you HAD TO SEE HOW IT ENDS! After nearly 10 minutes of slowly lowering her, her hull rested at 400 feet deep. Scott Reed noticed no change to the interior of the sub so we tied the descent line off and had lunch watching the video feed and talking about what we can now do with this depth rating verified. After awhile Scott Reed noticed the flood light’s battery became exhausted and the ambient light was so low he could not see inside the sub any longer. This made us all uncomfortable and Scott Reed concluded we must re-surface and add our LED lights before we go any deeper. We brought her up… BOY DID WE! Since she seemed unresponsive to the amount of air I added, I added more, then more and then more. Suddenly, only 20 feet from our port side, she erupted onto the surface in a cloud of bubbles faster than we had ever seen before! I was like Red October… only in miniature!

As the Great White broke the surface we felt a huge accomplishment and noticed her acrylic dome became increasingly foggy. Worried she had leaked, we quickly opened her up and checked. The dome was FREEZING!!! The water temperature was so cold that the dome frosted up when it hit the surface air. We found no water inside! She was perfect!

Now was the moment of truth. The next dive was to the end of the rope… 500 feet!

With a sense of accomplishment, confidence and parallel sense of catastrophic-failure-looming, we prepped her for the deep dive. Sid bravely swam out and vented the ballast pontoons submerging the sub. Almost immediately, Scott Reed noticed the video feed shifted off center and then went black. Tom quickly arrested the descent of the sub , then we raised the sub and began to access what happened. Sid disconnect the camera and Scott Reed brought it up to check it out. He found that the power cable inside the boat was unplugged (power failure solved) and the mounting bold was loose (loss of camera center solved)

Tom and Sid jumped into the water and reinstalled the camera and re-sealed the dome hatch. The team re-set the dive and Sid opened the valves for the last time. The sub quietly drifted down into obscurity. Scott Reed watched the monitor with ever more intensity as the sub descended down to and past 400 feet deep. Unexpectedly, Tom announced we were out of air-hose before he ran out of rope (which was marked at 500 feet). He arrested the descent and I worked the air-hose trying to determine what happened. After a few seconds I determined the air-hose either shrank a few feet due to cold water or it was wrapped up making it up to 20 feet shorter. We tied the rope off at 480 feet deep… just 20 feet from our target of 500 feet. 480 feet was all we were going to get… so we settled in to watch the video of our little sub while it rested in the eternal darkness of Lake Tahoe where less-than 10 people had ever been to before in Lake Tahoe’s history.

An hour creeped by as I monitored time on my beautiful Luminox watch… and we all texted to our families telling them what was happening. At one hour and five minutes, we all took up our stations and began to raise the sub. Unfortunately, the sub had had a great time underwater in the current and spun around approximately 20-25 times causing the video cable, air-hose and strength member (rope) to create a mess like I have not seen since… well… the last time we did something like this (deepwater filming for Giant Squid off La Jolla CA last winter). Deepwater work with umbilicals is a curse to me… nothing ever stays straight and orderly.

After about 10 minutes of trying to bring the sub up with the winch and not having any luck, we decided to inflate the pontoons while backing down so we were not directly overhead. We inflated and waited. It seemed to take forever so I added more air…and more air…and more air. We scanned the area behind us and sure enough, she erupted to the surface in a cloud of bubbles from the over-pressure relief valves…. but in perfect condition. SHE MADE IT TO 500 FEET AND BACK INTACT!

We uncoiled the mess of air-hose, rope line and video cable and prepped her for tow back to shore. We were all extremely happy at our (as UVP Executive Director- Kerry Franciscovich texted to me) “Little Sub That Could”!

As we brought the sub back to the Loomis home, we began to evaluate the sub in detail. The first thing we checked was the dome hatch. It had zero metallurgical effect from the deep water testing and the acrylic was perfect! All of the acrylic ports had no observed problems. The side (old thruster ports) thread caps did leak but the huge internal ball valves prevented any leaks. All thru-hulls were in perfect condition.

We did notice that both pontoon bags were 1/6 full of water. After a quick evaluation I determined that they filled with water from the inflation air-hoses we put together. Some of the air-hose fittings were only hand tight. When we lowered the sub with these hoses un-charged water ingress occurred from the increased pressure (basically filling them). When I opened the SCUBA air-tank valve to inflate the ballast pontoons remotely, the water in the air-hoses was pushed into the pontoons. This was a test system problem, not a submersible problem.

I am proud to announce that the Great White did these deep dives with no failures and no problems!

Now, she is located at Scott Reed’s home and we are are going to add stronger thrusters and add bigger ballast tanks along with a flat-bed deck on her back. An important update is the addition of two downward looking cameras with interior monitors so we can look “through” the sub floor and see what is directly below and in back of the sub.

September will be the most important mission the UVP has yet undertaken. We will work with our own sub, deeper and longer in Lake Tahoe and Fallen Leaf Lake than ever before. Our future is brilliantly bright!

CEO & Founder

Undersea Voyager Project

www.underseavoyagerproject.org